Types of valves

There are valves that can be used in low-temperature fields such as liquid hydrogen, liquid nitrogen, and liquefied natural gas (LNG), valves that can be used in high-temperature fields such as steam, valves that can be used with highly corrosive chemical liquids, powders and so on. We design and manufacture according to customer specifications.

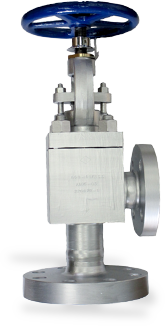

Globe valves

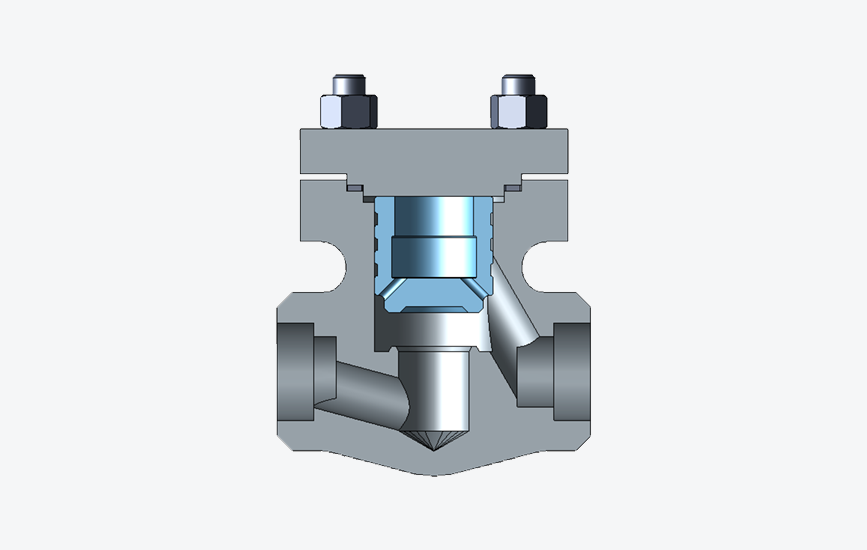

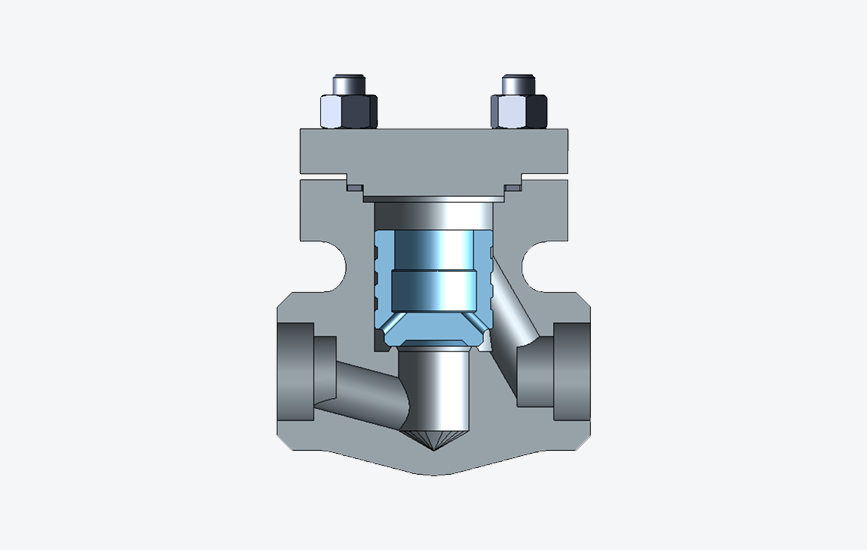

About Globe valves

“Globe valves” are valves with spherical body shapes. They are also called "stop valves" because they are excellent at regulating the flow rate of liquids and gases that pass through them,

and at the same time they have high performance in stopping the flow of fluids.

We also offer rubber-lined globe valves that have proven records of use in seawater, etc.

Features

Excellent at fluid flow rate adjustment

High performance in firmly stopping the flow of fluid

There are also valves such as “needle valves” and “angle valves”

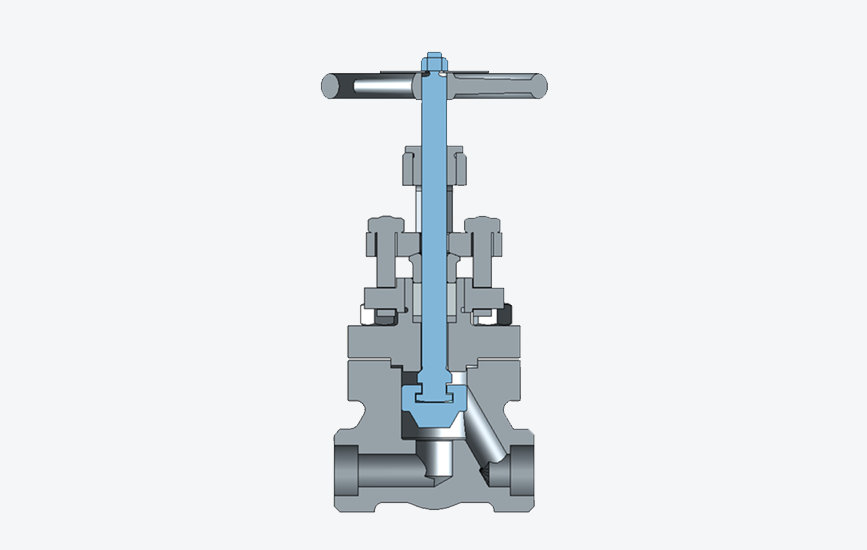

Valve Structure

Production Range

| Nominal pressure | 150LB~2500LB, 10K~63K |

|---|---|

| Size | 8A~600A, 3/8B~24B [varies depending on pressure] |

| Operation | manual operation, air operation, motor operation etc… |

| Body material | carbon steel, stainless steel, cast iron etc… |

Gate valves

About Gate valves

They are also called “gate valves”. Since the flow path is straight and the pressure loss is small, it is used for the purpose of allowing the fluid to flow vigorously in a completely open state or to stop the fluid by completely closing it. Hirata valve industry also offer rubber-lined gate

valves that have proven records of use in seawater, etc.

Features

Straight flow path with less pressure loss

It is used for the purpose of allowing the fluid to flow vigorously or to stop the fluid by completely closing it

It is not used to adjust the flow rate with intermediate opening

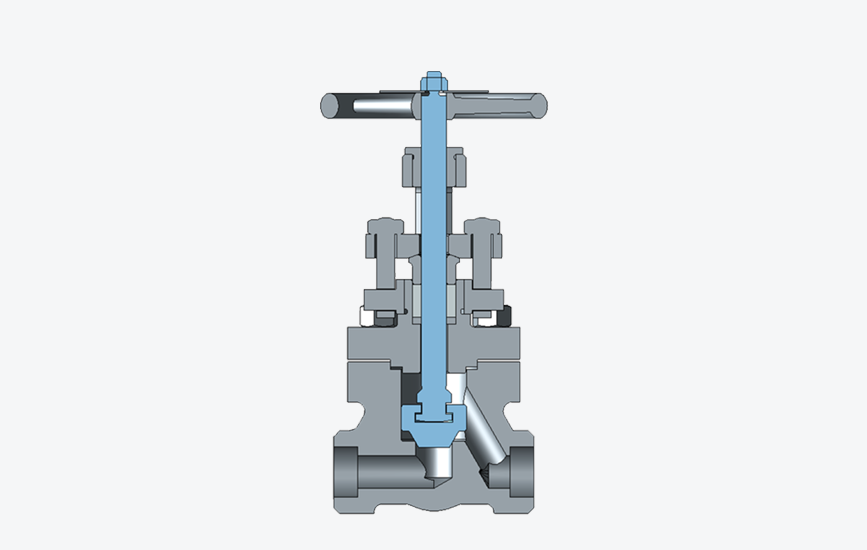

Valve Structure

Production Range

| Nominal pressure | 150LB~2500LB, 10K~63K |

|---|---|

| Size | 15A~1500A, 1/2B~60B [varies depending on pressure] |

| Operation | manual operation, air operation, motor operation etc… |

| Body material | carbon steel, stainless steel, cast iron etc… |

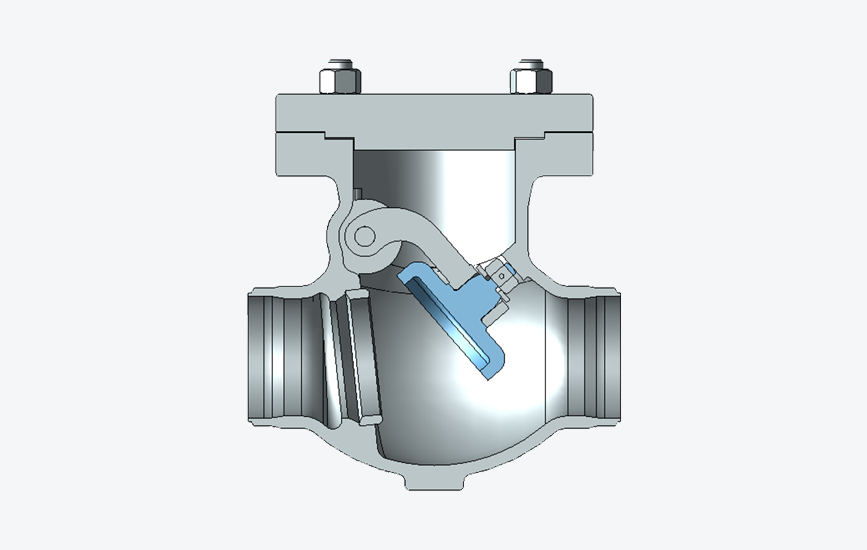

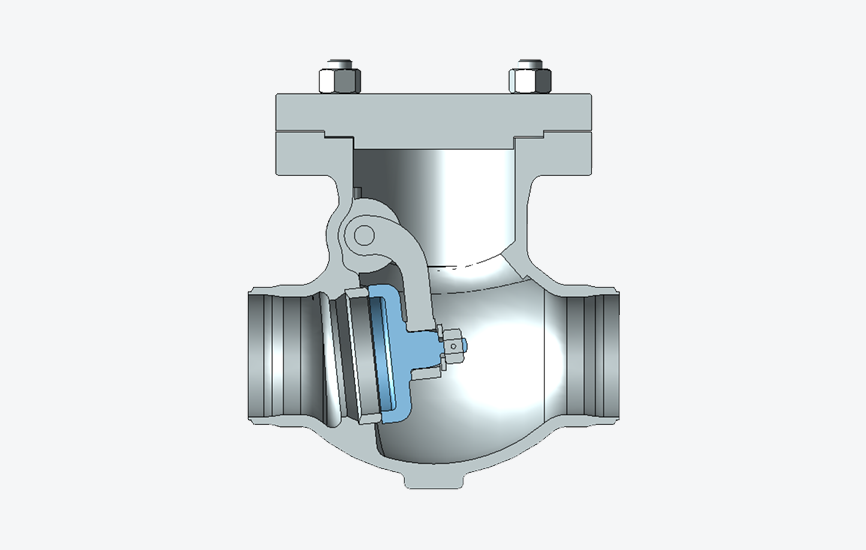

Check valves

About Check valves

It is called "check valves" in English. It is responsible for stopping backflow in piping. We also offer full rubber-lined valves that have proven records of use in seawater, etc.

Features

Prevents backflow smoothly without causing excess flow in the fluid

Stable operating conditions even at low flow rates

Excellent maintainability and achieving significant cost reduction

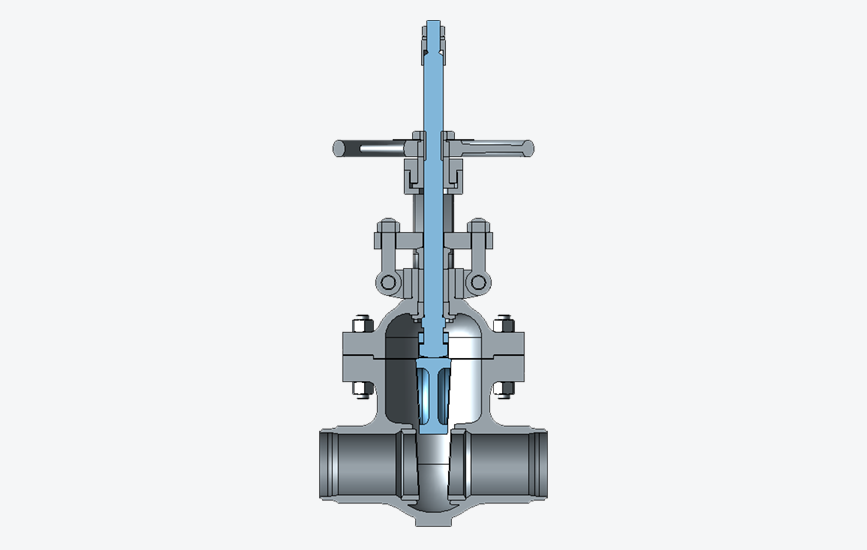

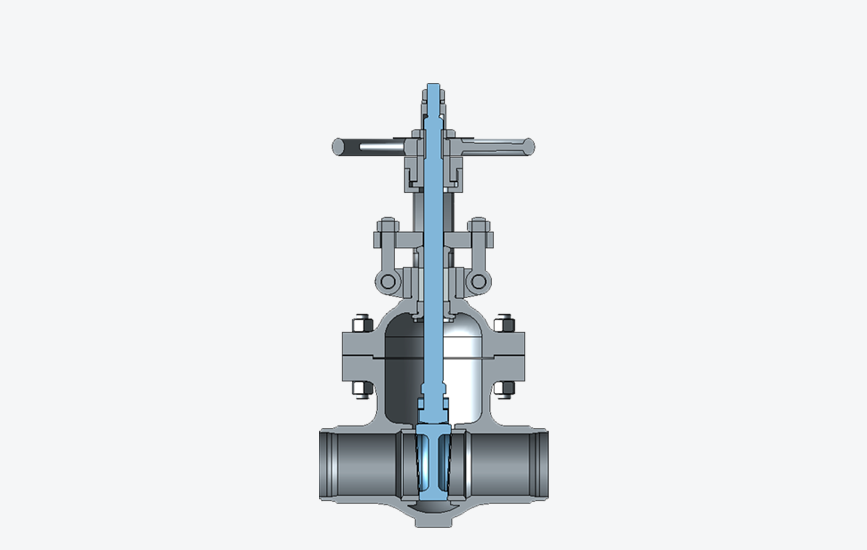

Valve Structure

Valve Structure

Production Range

| Nominal pressure | 150LB~2500LB, 10K~63K |

|---|---|

| Size |

swing check valve:20A~1500A, 3/4B~60B [varies depending on pressure] lift check valve:8A~350A, 3/8B~14B |

| Body material |

swing check valve:carbon steel, stainless steel, cast iron etc… lift check valve:carbon steel, stainless steel etc… |

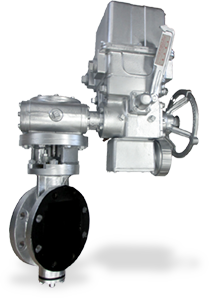

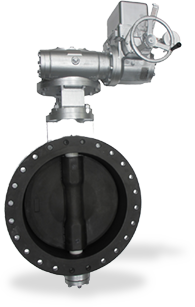

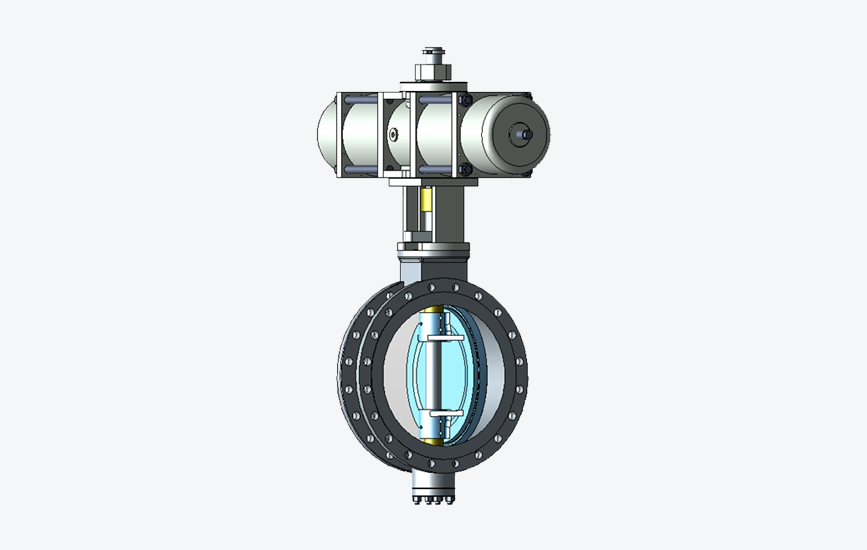

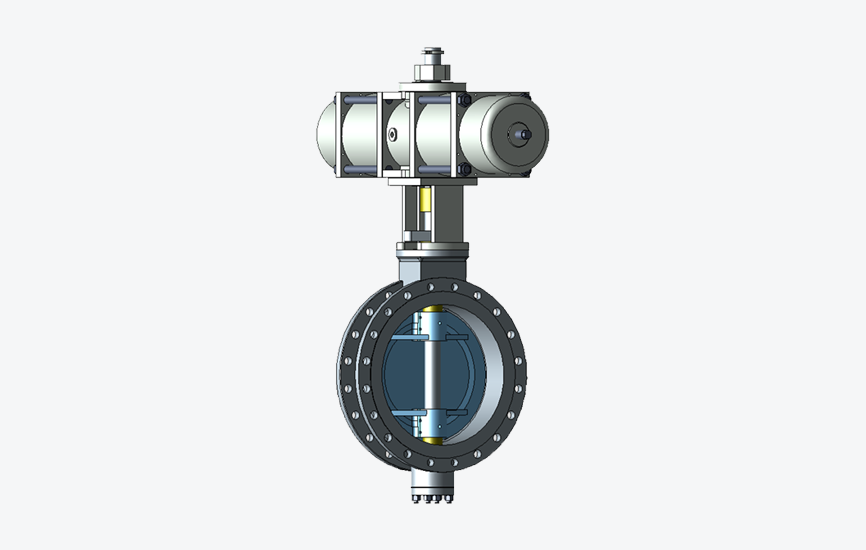

Butterfly valves

About Butterfly valves

It is characterized by opening and closing by rotating the disc in the flow path by 90°, and unlike ball valves, it has the advantage of being able to be installed in a small space.

Hirata valve industry offers metal seats and rubber seats for valve seats. We also offer full rubber-lined valves that have proven records of use in seawater, etc.

Features

It can be installed in a relatively small space and requires less maintenance

We also have a metal sheet type that leaks less even in a high temperature range

Valve Structure

Production Range

| Nominal pressure | 150LB, 5K, 10K |

|---|---|

| Size | 50A~1500A, 2B~60B [varies depending on pressure] |

| Operation | manual operation, air operation, motor operation etc… |

| Body material | carbon steel, stainless steel, cast iron etc… |

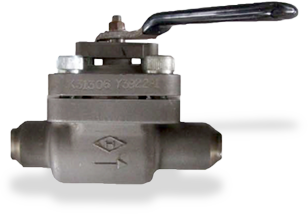

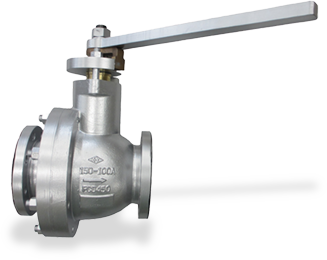

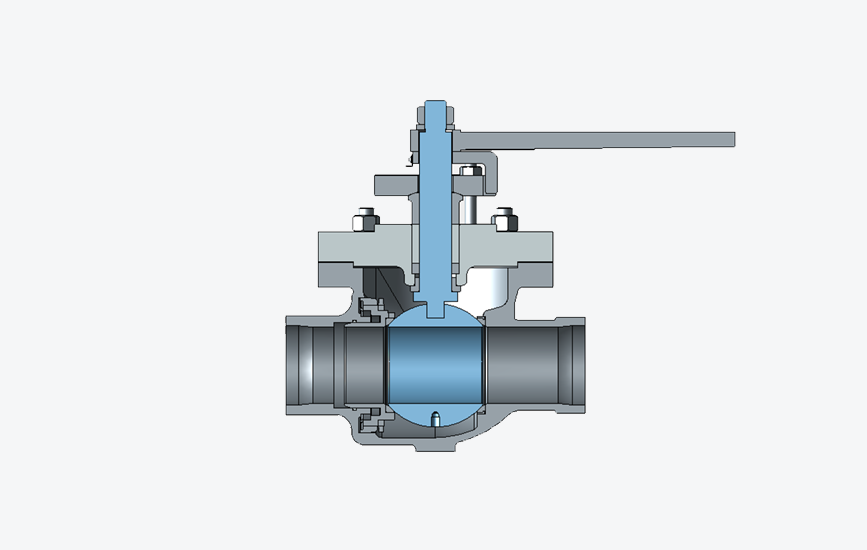

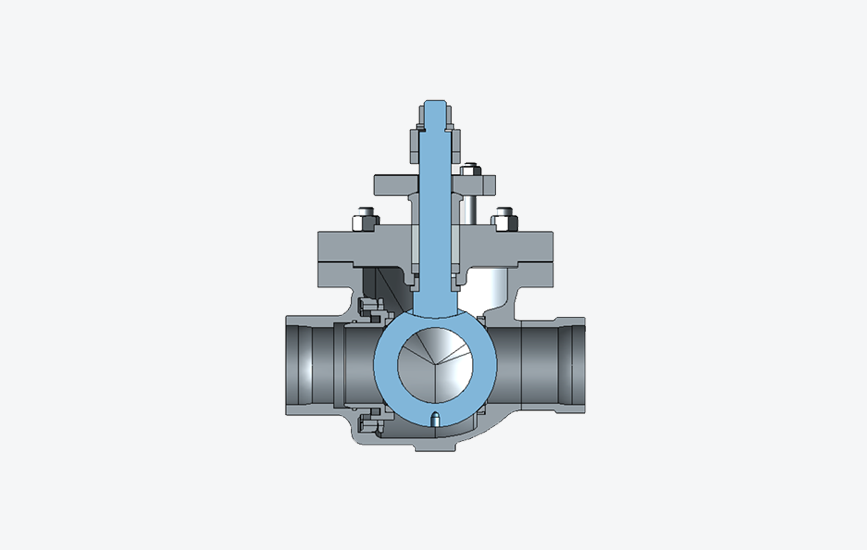

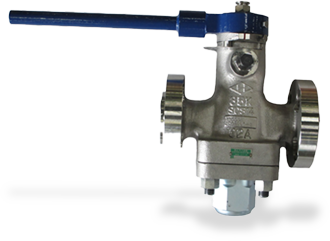

Ball valves

About Ball valves

A valve in which a ball with a hole through it serves as the valve body. If the direction of this

hole is aligned with the pipeline, the fluid can pass through, and if the direction is changed, the fluid can be stopped. Hirata valve industry also offer rubber-lined ball valves that have proven records of use in seawater, etc.

Features

Can handle sudden opening and closing

It is also possible to make it a three-way valve

We select the most suitable seat material according to the fluid temperature

Valve Structure

Production Range

| Nominal pressure | 150LB~1500LB, 10K~63K |

|---|---|

| Size | 8A~400A, 3/4B~16B [varies depending on pressure] |

| Operation | manual operation, air operation, motor operation etc… |

| Body material | carbon steel, stainless steel, cast iron etc… |

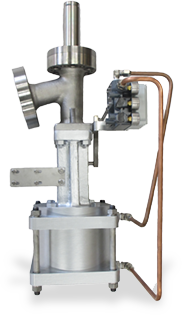

Safety valves

About Safety valves

It is installed as a safety device for various pressure vessels and piping lines such as boilers.

It prevents the internal pressure of pressure vessels from rising above the specified value, and functions as the ultimate safety device to prevent damage to the vessel itself and equipment, or disaster caused by explosion destruction, etc.

Features

Widely used for various gases, air, steam and liquids

Operates quickly when pressure is above a given value

A wide variety of types are available according to the application and fluid

Production Range

| Size | 8A~250A [varies by valve type] |

|---|---|

| Body material | carbon steel, stainless steel, cast iron etc… |

Discharge valves

About Discharge valves

Also known as a "flush valve" or "tank bottom valve", the discharge valve is often installed at the bottom of the tank. The basic seal structure is the same as a globe valve. When the compressor is in the compression process, the top spring serves as a lid to increase the compression efficiency.

Features

Manual and air operation are possible

There are 3 types: ascending type, descending type, and ram type

Production Range

| Nominal pressure | 150LB〜1500LB, 5K〜63K |

|---|---|

| Size | 15A〜400A [varies depending on pressure] |

| Operation | manual operation, air operation |

| Body material | carbon steel, stainless steel, cast iron etc… |